What is a Mechanical Fitter? A Practical Guide (what is a mechanical fitter)

- Ricky Cohen

- 2 days ago

- 10 min read

In simple terms, a mechanical fitter is the skilled professional who builds, installs, and keeps industrial machinery running. They are the practical experts who take complex engineering plans and turn them into real, working equipment. You could almost think of them as the surgeons of the machine world, making sure every single part functions exactly as it should.

Understanding the Role of a Mechanical Fitter

So, what does a mechanical fitter actually do on a day-to-day basis? Picture a brand-new factory floor getting its first production line. While an engineer might have designed the layout on a computer, it's the mechanical fitter who is physically on the ground, carefully putting together the conveyor belts, robotic arms, and hydraulic presses. They have to interpret intricate technical drawings, align high-precision components, and guarantee every piece moves in perfect sync.

But their job isn't finished once the machinery is up and running. They're also the first-responders when things go wrong. When a critical pump fails or a gearbox grinds to a halt, the fitter steps in to diagnose the problem. They'll methodically find the root cause, dismantle the unit, fix or swap out the broken parts, and put it all back together according to exact specifications. This mix of proactive installation and reactive problem-solving makes them absolutely vital to any industrial operation.

A Mechanical Fitter's Core Responsibilities at a Glance

The role is a fascinating blend of deep technical knowledge, hands-on ability, and sharp analytical thinking. While a fitter’s daily tasks can change, they generally revolve around a few key areas.

The table below gives a quick overview of what the job entails.

Core Function | Key Responsibilities | Essential Trait |

|---|---|---|

Assembly & Installation | Following detailed blueprints to construct and install everything from small parts to entire systems. | Precision |

Maintenance & Repair | Carrying out routine servicing and emergency repairs to prevent costly downtime and prolong equipment life. | Proactiveness |

Diagnostics | Using specialised tools and experience to pinpoint mechanical, hydraulic, or pneumatic faults. | Problem-Solving |

Testing & Commissioning | Making sure new or repaired equipment runs safely and meets all performance standards before handover. | Thoroughness |

Essentially, these responsibilities show that a fitter is the critical connection between an engineering concept and an operational reality.

A mechanical fitter is the hands-on problem-solver who ensures the physical machinery of our industries works correctly, safely, and efficiently, day in and day out.

This kind of expertise is essential in sectors like manufacturing, construction, energy, and beyond. If you're drawn to this practical and challenging field, it's worth exploring the different mechanical and electrical roles available to see just how high the demand is for these skills.

A Day in the Life of a Mechanical Fitter

Forget the nine-to-five grind at a desk; for a mechanical fitter, no two days are ever the same. The role is a fascinating blend of meticulous planning and firefighting unexpected problems, demanding a sharp mind and an even sharper set of skills.

A typical day often kicks off not with a spanner in hand, but with a plan. You might start the morning in a team briefing, poring over technical drawings and schematics for a new piece of kit. It’s your job to translate those lines and numbers on a page into a real-world, step-by-step assembly plan.

This means getting to grips with the machine's anatomy—identifying every component, triple-checking measurements, and picturing how it all fits together. One day it's a massive hydraulic press, the next it's a sprawling conveyor system.

From Plan to Action

Once the blueprint is crystal clear in your head, it’s time to get hands-on. You could be on a factory floor, piecing together a brand-new machine where absolute precision is everything. Every single bolt needs to be tightened to the exact torque, and each part aligned with millimetre-perfect accuracy to stop problems from developing down the line.

Then again, your day could flip in an instant. An urgent call comes through – there’s a critical breakdown on a major construction site. A hydraulic pump on an excavator has given up, grinding a multi-million-pound project to a halt.

At its heart, a fitter’s day is about solving problems under pressure. You might go from a calm, controlled installation in the morning to a high-stakes emergency repair in the afternoon, but the standard of your work can never drop.

This is where a fitter's diagnostic instincts really come into their own. You have to systematically hunt down the fault, often in a loud, dirty, and difficult environment. Is it a leaky seal? A blocked valve? Or maybe an electrical fault cutting power to the motor?

Using a combination of experience, instinct, and testing gear, you’ll pinpoint the culprit, get hold of the right replacement parts, and carry out the repair swiftly and safely. A good day’s work means getting that vital piece of machinery back up and running, saving the client from a world of expensive downtime.

If you’re getting ready to step into this kind of fast-paced environment, check out our guide on essential tips for your first day at work in construction.

The Skills and Qualifications You Need to Succeed

Becoming a top-notch mechanical fitter isn’t just about being good with your hands. It’s a carefully balanced mix of formal qualifications and skills you can only learn on the job.

In the UK, the most well-trodden path is completing a Level 3 apprenticeship in Mechanical Engineering or a similar field. This route is fantastic because it gets you earning while you learn, combining practical, on-the-job training with structured classroom theory.

Beyond the apprenticeship, certain certifications are non-negotiable for site work. Holding a valid CSCS (Construction Skills Certification Scheme) card, for example, is often a basic requirement just to get your boots on a UK construction site. It's your passport to proving you understand critical health and safety standards.

Essential On-the-Job Abilities

While qualifications open doors, it's your practical skills that will define your career. To excel day-to-day, you really need to master these core abilities:

Reading Technical Drawings: The ability to look at a complex blueprint or engineering diagram and see the finished product in your mind's eye is fundamental. Accuracy here is everything.

Understanding Systems: You need a solid grasp of how hydraulic and pneumatic systems work. This knowledge is what separates a good fitter from a great one when it comes to troubleshooting a stubborn machine.

Welding and Fabrication: Strong skills in welding, cutting, and shaping metal are vital. You'll often be called upon to make custom parts or perform intricate repairs that require a skilled hand.

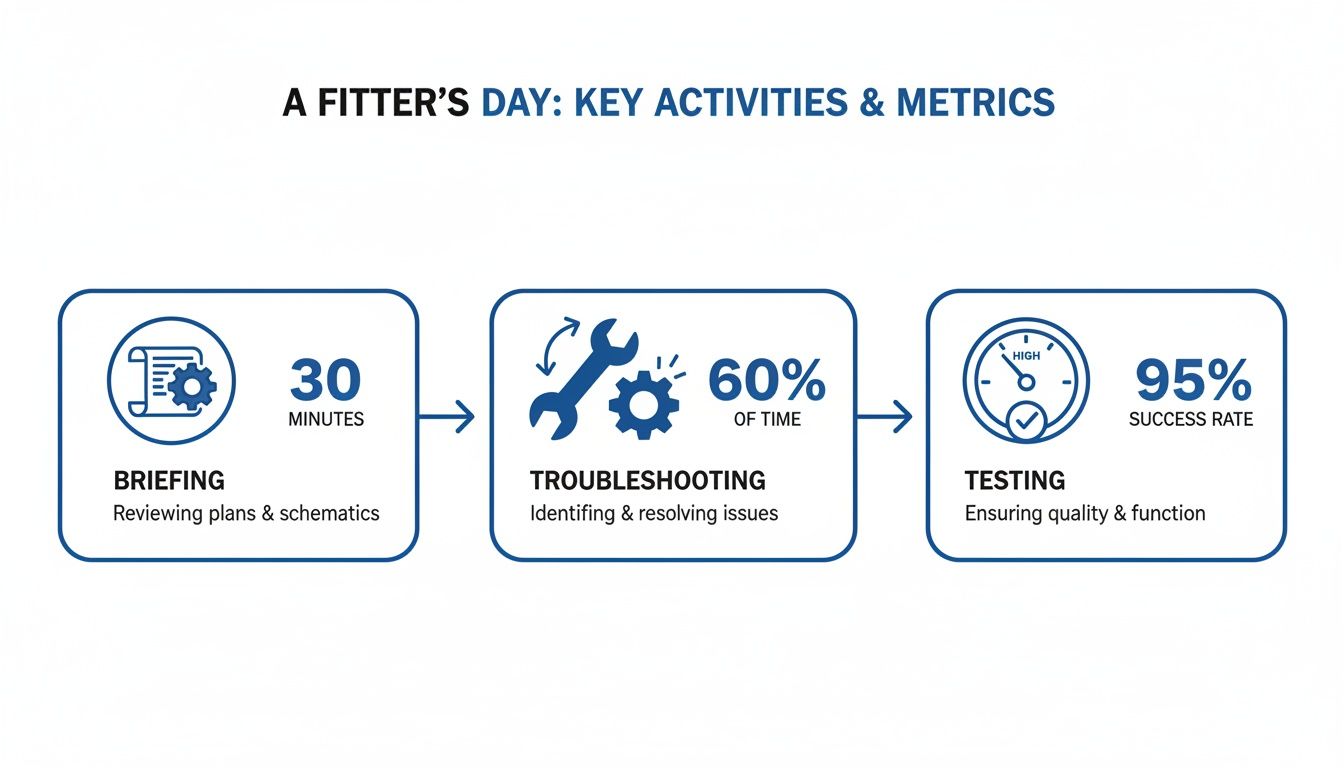

The graphic below gives a little insight into how these skills play out during a typical day.

As you can see, a fitter's time is a blend of planning, hands-on problem-solving, and final testing. When it comes time to apply for jobs, it's crucial to present this technical background clearly. Using a specialised Mechanical Engineer Resume Template can make a huge difference in how your experience is perceived.

Don't underestimate the "soft skills," either. They're just as important. A mechanical fitter needs to be a clear communicator, a sharp problem-solver, and absolutely committed to keeping the work environment safe for everyone.

The demand for people with this blend of technical and personal skills is sky-high. In fact, data shows that mechanical fitting roles are among the toughest to fill in the UK, accounting for 41.1% of all key occupations facing shortages. This really underscores the job security and value placed on skilled fitters in today's market.

Where Can a Mechanical Fitter Work?

The skills you develop as a mechanical fitter aren't just needed in one specific place; they are the backbone of almost any industry that uses machinery. This incredible versatility opens doors to a huge range of working environments, from the buzz of a factory floor to the ever-changing landscape of a construction site.

Picture a massive car manufacturing plant. Mechanical fitters are the ones on the ground, installing, servicing, and fine-tuning the complex assembly lines that keep everything running smoothly. If just one robotic arm or conveyor belt goes down, it can bring the entire operation to a standstill, which makes the fitter’s job absolutely essential.

Key Industries and Work Environments

The need for skilled fitters goes far beyond just factories. Here are a handful of the major sectors where your expertise would be indispensable:

Construction: On major building projects, you'll be the go-to person for keeping heavy machinery like cranes, excavators, and bulldozers running, preventing the kind of costly downtime that can derail a project.

Logistics and Warehousing: Think about the massive, automated warehouses that power online shopping. Fitters are needed to maintain the robotic pickers and sorting systems that have to work flawlessly to hit tight delivery deadlines.

Energy and Utilities: Whether it's a traditional power station or a wind farm, fitters are there maintaining the turbines, pumps, and generators that keep the lights on for the rest of us.

The UK's construction industry is a perfect example of this demand. It currently employs around 42,740 plant mechanics and fitters, and it needs hundreds of new people every year just to replace those who are retiring. With 36.3% of UK construction firms reporting worker shortages, skilled fitters are more critical than ever. You can see just how deep this need runs in the Construction Leadership Council's latest skills plan.

A good mechanical fitter can find work almost anywhere machinery is involved. It’s one of the most stable and varied trades out there, allowing you to build a career that truly fits your interests, whether that’s in high-tech manufacturing or hands-on, on-site maintenance.

If you're ready to see what's out there, you can explore mechanical fitter jobs and find current openings across all these different sectors.

Your Career Path and Salary Expectations

Choosing a career as a mechanical fitter isn't just about getting a job; it's about stepping onto a well-defined and rewarding career ladder. In this trade, the more experience you gain and the more specialised your skills become, the more you're valued. That value translates directly into higher pay and more responsibility over time.

Most people get their start through an apprenticeship, which is a brilliant way to earn while you learn. As an apprentice, you can expect a starting salary somewhere in the region of £15,000 to £22,000 a year. The exact figure will depend on where you are in the country and the size of the company, but the key benefit is learning the fundamentals of the trade on the job, without racking up university debt.

Advancing Your Fitter Career

Once you've got your qualifications, your earning potential takes a healthy jump. A newly qualified mechanical fitter can typically earn between £25,000 and £35,000. Stick with it for a few years and get some solid experience under your belt, and you’ll likely see that figure climb into the £35,000 to £45,000 bracket.

The real money, though, often comes from becoming an expert in a specific area. If you develop sought-after skills in high-demand fields like hydraulics, pneumatics, or complex industrial control systems, you could command a salary well over £50,000.

A mechanical fitter's career isn't just a job; it's a ladder. With dedication and continuous learning, you can progress from the tools into senior leadership and management roles.

This progression isn't just about becoming a better fitter. Many experienced professionals eventually move off the tools and into leadership positions, where their deep, practical knowledge is invaluable.

Common next steps on the career path include:

Lead Fitter or Senior Technician: Taking charge of a small team and being the go-to person for the most challenging diagnostic problems.

Maintenance Supervisor or Foreman: Moving into management, where you'll be responsible for maintenance schedules, overseeing operations on site, and keeping the team safe and productive.

Project Engineer or Site Manager: Taking on even broader responsibilities, planning and executing major installation or maintenance projects from start to finish.

This clear, structured progression shows the long-term stability and potential that the trade offers. If you want to see how this role connects to the wider industry, take a look at our full guide to careers in construction.

The Future-Proof Fitter in a Green Economy

The role of a mechanical fitter isn't just a safe bet for a career; it's becoming absolutely vital as the UK pivots towards a greener future. The core skills you learn—assembly, maintenance, and diagnostics—are directly transferable to the booming renewable energy and sustainability sectors.

Just think about the colossal offshore wind turbines popping up around our coastline. Who do you think assembles those gigantic components and makes sure they run smoothly? Mechanical fitters. They're also the ones on the front line of retrofitting older industrial sites, upgrading machinery to boost energy efficiency and cut emissions.

Adapting Skills for a Greener Future

This shift towards green technology offers incredible long-term career security. At the end of the day, the fundamental principles of how machinery works don't really change, whether you’re working on a traditional factory line or in a state-of-the-art electric vehicle battery plant.

As the nation chases its net-zero targets, the demand for skilled technicians is set to explode. Take heat pumps, for example. The workforce needed to install them is expected to hit 70,000 by 2035. Mechanical fitters are perfectly placed to step into these roles, applying their tried-and-tested expertise to new, sustainable technologies. For a deeper dive, check out the excellent analysis in EngineeringUK's insightful report on how green infrastructure is shaping the workforce.

A mechanical fitter's skillset is future-proof. It is the practical foundation upon which the UK's green industrial revolution is being built, ensuring job relevance for decades to come.

Common Questions About Becoming a Mechanical Fitter

Thinking about a career as a mechanical fitter? It's a hands-on trade, so it’s natural to have a few questions before you dive in. Here are some straight answers to the queries we hear most often.

Do I Need a University Degree?

Not at all. In fact, a university degree isn't the typical path into this profession.

What really matters to employers is practical, hands-on experience. The most respected route is usually a Level 3 apprenticeship in an engineering field. Qualifications like these, along with NVQs, show you have the real-world skills needed for the job, which is far more valuable than a purely academic degree in this line of work.

Fitter vs. Mechanic: What's the Difference?

It really comes down to scale and scope. Think of a mechanical fitter as someone who works on huge, often stationary industrial machinery—the kind you’d find in a factory or on a production line. Their world revolves around assembling, installing, and maintaining this heavy equipment based on detailed technical drawings.

A mechanic, on the other hand, usually specialises in vehicles. They’re the experts you call to diagnose and fix engines and other moving parts on cars, lorries, and other mobile equipment. It’s a different kind of problem-solving for a different type of machine.

Is the Job Physically Demanding?

Yes, you can definitely expect a physical challenge. This isn't a desk job.

You'll likely spend a lot of time on your feet, lifting heavy components, and getting into all sorts of positions—sometimes in tight spaces or working at height. Being in good physical shape is a big plus, and having a serious commitment to health and safety is absolutely essential for staying safe and building a long career.

Ready to build your career as a mechanical fitter? Phoenix Gray Rec Ltd connects skilled tradespeople with leading employers across the UK. Find your next opportunity with us today.

Comments